Professional Pre- and Post-Treatment

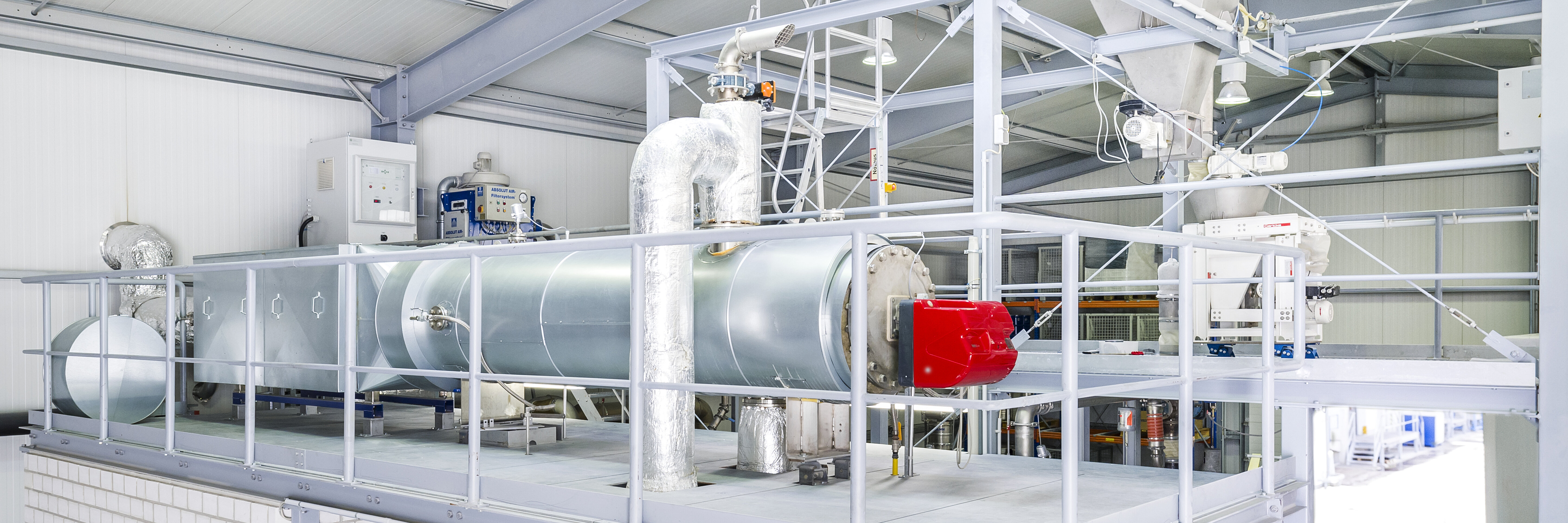

When you partner with us for thermal material conversion, you benefit from a complete service encompassing professional preparation, the thermal process itself, and expert follow-up. Our systems are designed on a modular basis and can be equipped with a range of additional units to manage critical upstream and downstream manufacturing steps seamlessly.

A cornerstone of this integrated approach is our reliable conveyor and dosing technology. It ensures raw materials are precisely metered and fed continuously into the process, even when handling fluctuating material properties or complex conveying routes. This capability enhances overall process reliability and guarantees consistently high product quality.

For environmental compliance and sustainability, we provide effective exhaust gas treatment solutions, including:

- Dust filters

- DeNOx systems

- Thermal afterburning systems

- Gas scrubbers

Our team of experts provides unwavering support at every stage. This commitment extends to our in-house workshop, which is equipped to make precise, individual adjustments to all available units to meet your specific requirements.

-

Conveying and Dosing Equipment

Conveying and Dosing Equipment

Precise dosing and reliable conveying of raw materials are fundamental to stable and efficient plant operation. This is especially critical when processing frequently changing reactants with variable properties. Our flexible and adaptable systems ensure not only a uniform material feed but also exact control over throughput quantities.

We select from gravimetric or volumetric dosing principles and employ various technologies—including screw conveyors, vibrating chutes, and pneumatic systems—based on your specific application. Choosing the optimal equipment requires deep expertise to guarantee process reliability and enable flawless integration into your overall operation.

Screw Conveyors Gravimetric dosing unit with screw feed Dosing belt scale Conveyor belts Volumetric dosing screws Displacement and peristaltic pumps Disc Conveyors Vibration chutes & conveyors Membrane pumps & Spraying lances Pneumatic Conveyors Gravimetric feeders Rotary feeders -

Exhaust Gas Treatment

Exhaust Gas Treatment

To ensure compliance with all regulatory standards and to exceed internal emission targets, we implement a suite of advanced exhaust gas aftertreatment processes and systems.

Thermal oxidizers and exhaust gas cleaning DeNOx systems to denitrogenize the exhaust gas Filter systems to remove dust from the exhaust gas Gas scrubbers, venture-scrubbers (wet gas scrubbers) for the removal of particulates and absorbable gases (acidic and alkaline washes) Dust analysis in the treated gas, final police filter Use of adsorbents to remove acidic components