How Rotary Kilns Work

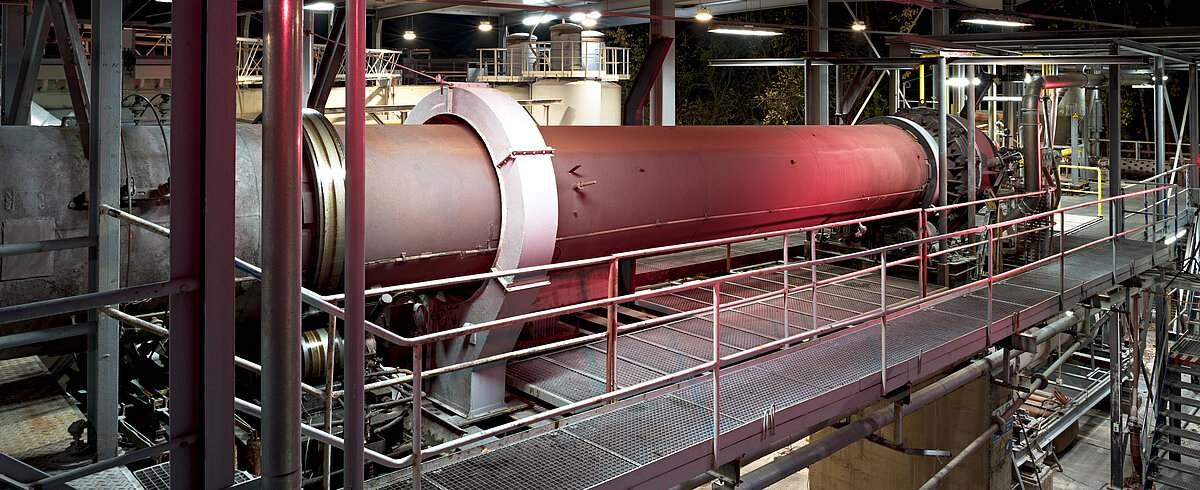

Rotary kilns (sometimes called calciners or rotary furnaces) are used for thermal treatment processes such as calcination, sintering, pyrolysis and firing, as well as for oxidation and reduction. These treatments can be applied to powders, granulates, suspensions and green bodies. A rotary kiln consists of a cylindrical, rotating body mounted between stationary material feed and outlet housings. The constant turning of the kiln body mixes the material, ensuring that it is processed homogeneously. Rotary kilns are heated either directly (inside the kiln chamber) or indirectly (from outside), depending upon the requirements of the application.

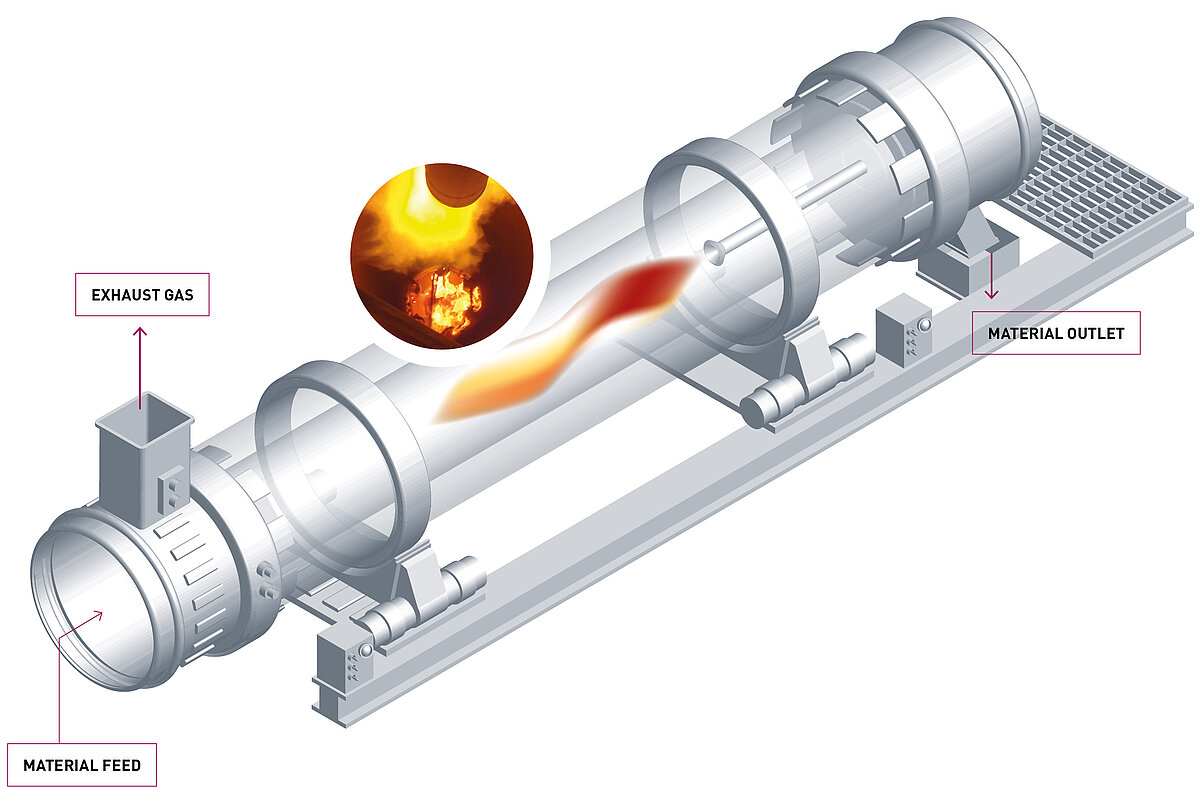

Direct Fired Rotary Kiln

In a direct-fired rotary kiln, the burner is situated inside the kiln body, that is, inside the reaction chamber. The material is heated directly by the burner flame and the stream of hot gas produced by the burner. These kilns are usually lined with refractory (heat-resistant) material so that they can be operated at higher temperatures than kilns with plain metal tubes. Directly fired kilns are highly robust and easily scalable and can be used to achieve high throughput rates with relatively low production costs.

Facts & Data

- 4 direct heated rotary kilns

- Temperature range: 100 – 1,550°C

- Residence time: 15 – 180 minutes

- Reaction modes: continuous, batch, co-current, counter-current

- Typical Processes: calcination , sintering , reduction , oxidation and drying

- Rotary Kiln

- Characteristics & Capacities

Kiln

nameHeated

kiln

length

[m]Inner diameter

[m]Temperature

range

[°C]Raw material

throughput

[kg/h]Mode of operation

Special features

Heating

typeGDO

12

1

up to 1,500

150 – 1,500

counter-current (co-current)

raw material silo, 10 m rotary cooler, cyclone preheater

natural gas

MDO

4

0.6

up to 1,250

50 – 500

counter-current

rotary cooler, cyclone preheater

natural gas

KDO

7

0.3

up to 1,550

10 – 100

counter-current or co-current

vibration cooler, rotary cooler, reducing gas atmosphere possible, afterburner

natural gas

BDO

0.6

0.35

up to 1,000

15 l per batch

batch operation only

batch kiln for small quantities

natural gas

- Downloads

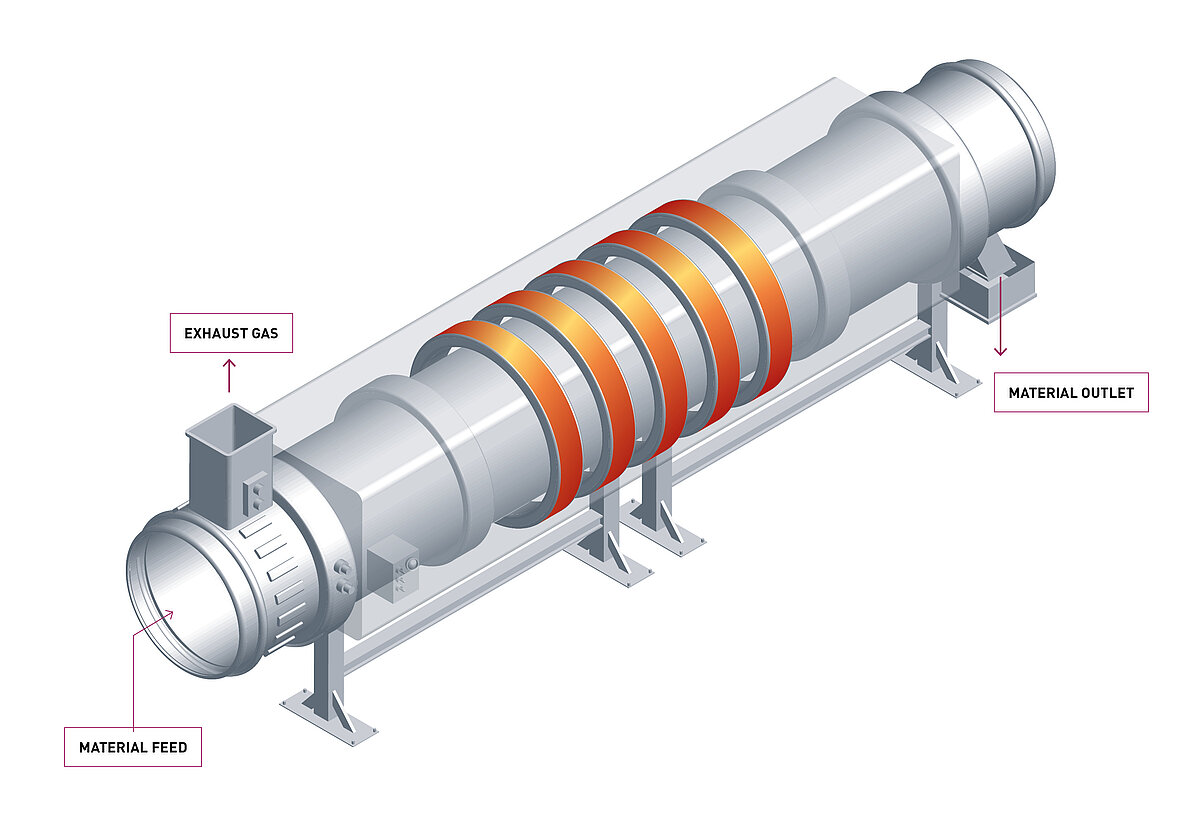

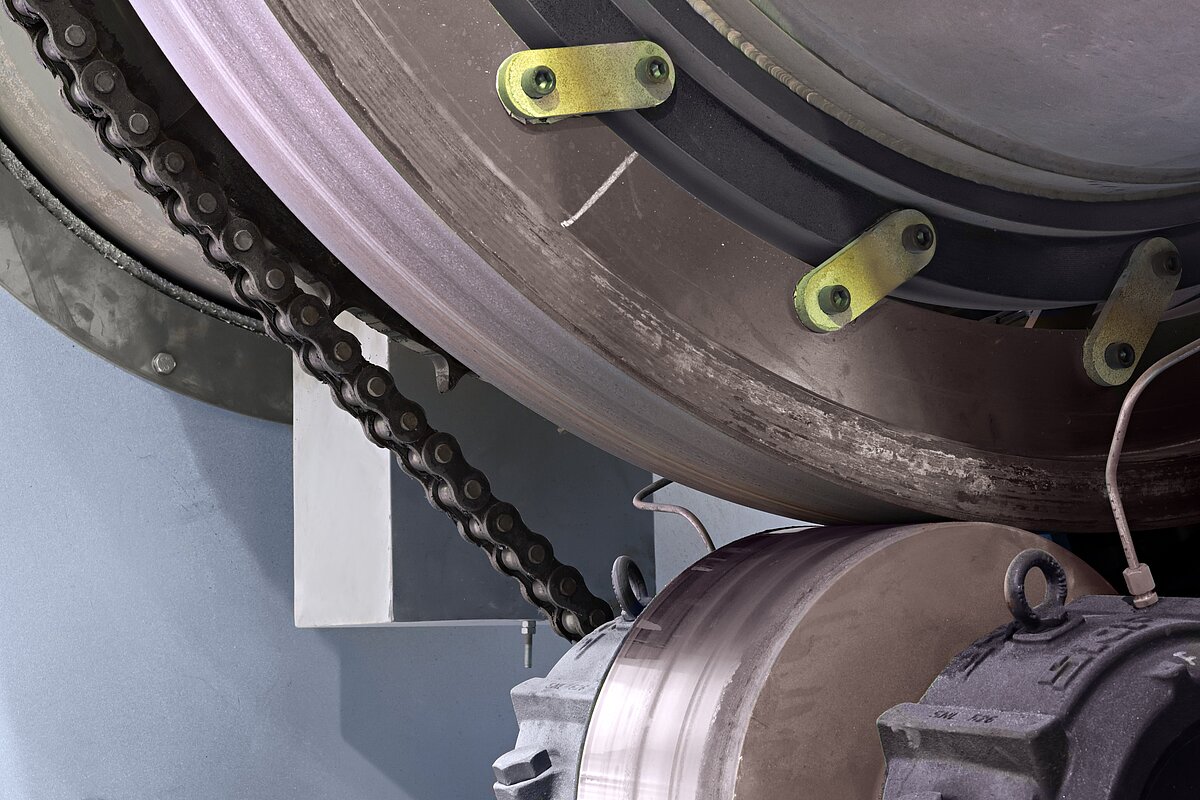

Indirect Fired Rotary Kilns

In contrast to directly fired kilns, indirect fired rotary kilns (also called rotary calciners) are equipped with natural gas burners or electric heating elements located outside the reaction chamber, so that the heat is transferred to the interior through the kiln shell. This arrangement makes it easy to operate the kiln with a controlled gas atmosphere in the reaction chamber (e.g. inert or reducing). Because combustion gases are kept out of the reaction chamber, the gas volume flow in an indirectly fired kiln is generally lower than in directly fired kilns. This means the indirect rotary kilns are excellent for treatment of very fine powders. They are also easier to clean, so that cross-contamination of materials can be more effectively prevented.

Facts & Data

- 12 indirect heated rotary kilns

- Temperature range: 100 – 1,400°C

- Residence time: 15 – 180 minutes

- Reaction modes: continuous, co-current, counter-current, batch

- Typical Processes: pyrolysis, calcination, reduction and surface treatment of catalyst supports

- Rotary Kiln

- Characteristics & Capacities

Kiln

nameHeated

kiln

length

[m]Inner diameter

[m]Temperature

range

[°C]Raw material

throughput

[kg/h]Mode of operation

Special features

Heating

typeIDO 10

7

1

300 - 1,150

100 - 1,000

counter-current

5 heating zones

natural gas

IDO 9

7

1

300 - 1,100

100 - 1,000

counter-current

defined gas atmosphere,

5 heating zones, thermal oxidizernatural gas

IDO 11 4.7 0.6 100 – 1,150 40 – 400 counter-current Inert and reducing, hydrogen-atmosphere,

thermal oxidizerelectrical

IDO 3

4

0.5

300 - 1,150

25 - 250

counter-current or

co-current, batch operation possibledefined gas atmosphere,

6 heating zones, thermal oxidizernatural gas

IDO 6 3.75 0.45 100 – 900 15 – 150 counter-current defined gas atmosphere,

3 heating zones, thermal oxidizer, DeNOxelectrical

IDO 5

3

0.4

300 - 1,150

10 - 100

counter-current or

co-currentdefined gas atmosphere,

3 heating zones, thermal oxidizerelectrical*

IDO 1

3

0.4

50 - 1,150

10 - 100

counter-current or

co-current, batch operation possibledefined gas atmosphere,

3 heating zones, thermal oxidizerelectrical

IDO 2

3

0.4

50 - 1,150

10 - 100

counter-current or

co-current, batch operation possibledefined gas atmosphere, 4 heating zones

electrical

IDO 7 2.3 0.254 100 – 1,000 3 – 30 counter-current or

co-currentInert and reducing,

thermal oxidizerelectrical

IDO 4

1

0.1

50 - 1,100

0.1 - 2

counter-current or

co-current, batch operation possibledefined gas atmosphere, thermal oxidizer

electrical

IDO 8

1

0.1

100 - 1,400

0.1 - 2

counter-current or

co-current, batch operation possibleceramic & metal tube, defined gas atmosphere, thermal oxidizer

electrical

IDO 12 0.9 0.4 50 - 1,100 ca. 30 l / batch batch operation only electrical

LBO 0.5 0.1 200 - 1,100

< 0,5 l / Batch batch operation only defined gas atmosphere electrical *in construction

- Downloads