IBUpart® CeO2 Product Variants and Application in Polishing Suspensions

Depending on the requirements of the materials being treated, different specifications of the polishing agent used to produce the polishing suspension are necessary. Cerium oxides with larger primary particle size and lower specific surface areas, for example, have higher removal rates and are particularly suitable for polishing glasses for high-end or boutique optical applications. The high surface area IBUpart® Cerium Oxide 40, on the other hand, consists of nanoparticles and can be used in the production of silicon wafers and semiconductors.

IBUpart® CeO2 2 | IBUpart® CeO2 40 | |

| Specific surface area | 2 ± 1 m2/g | 40 ± 2 m2/g |

| Particle size (d50) | 1.5 – 2.0 µm | 0.015 – 0.02 µm |

| Purity | 95 – 98 wt.% | > 99 wt.% |

| Bulk density | 1.45 – 2.00 g/cm3 | 0.3 – 0.4 g/cm3 |

| Annealing loss | 0.4 – 1.5 % | / |

| pH value | 5.91 – 6.28 | / |

| Possible applications |

|

|

| Datasheet | Download | Download |

Background and Production of Cerium Oxide

Cerium oxide, or cerium dioxide, (CeO2) is the stable oxide of the rare earth metal cerium and the most abundant element of the lanthanides. It can also be referred to as cerium. In natural deposits, cerium is present along with other rare earth elements. To separate the lanthanides, the extracted cerium ore is digested with strong acids or bases. Subsequent oxidation of the dissolved components allows Ce(IV) compounds to be selectively precipitated. Calcination of the precipitation products in rotary kilns leads to the formation of a yellow solid oxide – cerium oxide!

With an annual global production of 68,500 tons (2019), CeO2 is the most processed oxide of all the elements of the rare earth metals and finds its largest application in glass processing. Here, cerium oxide is used as a polishing agent and as an additive for glasses, since cerium oxide particles can produce a particularly smooth glass surface during the polishing process due to complex surface chemistry. The special polishing effect is the result of a combination of chemical dissolution, the deposition of material and a mechanical removal process (CMP: chemical-mechanical polishing).

As a component of the 3-way catalytic converter, CeO2 is also processed in most automobiles with gasoline engines: Cerium oxide has a high oxygen storage capacity and can provide sufficient oxidant for the catalytic combustion processes.

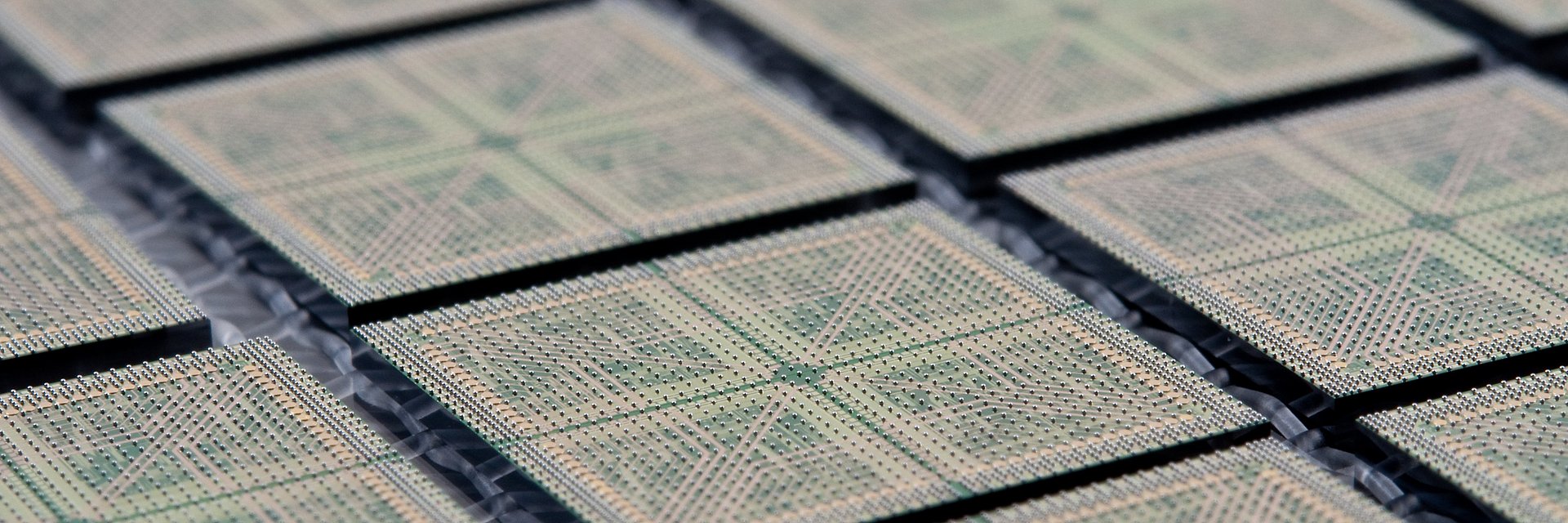

The semiconductor industry also has a growing need for high-purity cerium oxide-based polishing agents due to the steadily ongoing miniaturization of circuits. Slurries containing CeO2 nanoparticles can meet the high demands of semiconductor technology. Due to the primarily chemical polishing processes, low removal rates can be achieved with cerium dioxide when processing silicon wafers.