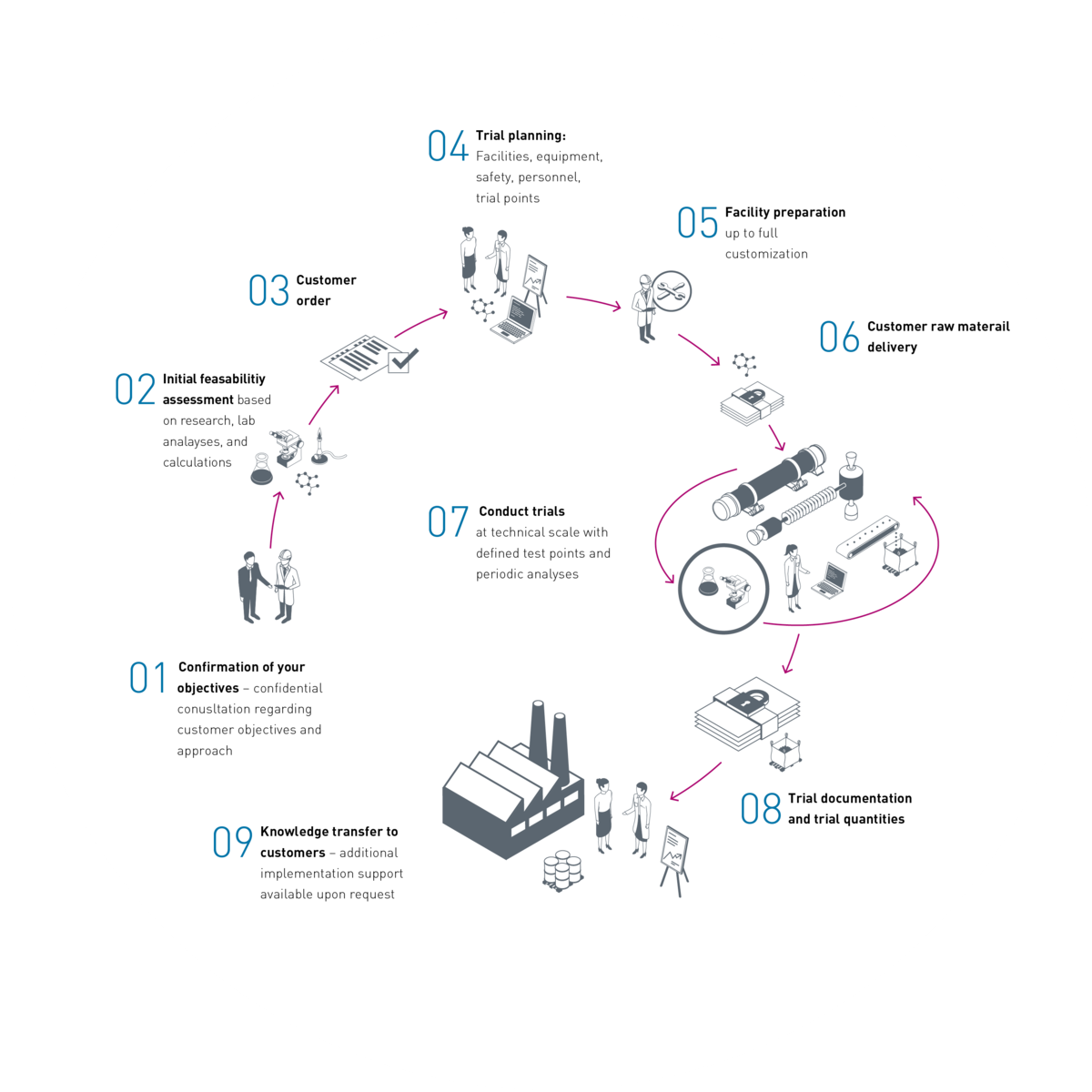

Scale-up Trials for Thermal Processes

It is often the case that experimenting with new ideas and product innovations on face value seems simple enough. However, when the goal is to reach a defined set of material characteristics, more often than not, challenges must be overcome.

Scale-up trials have the potential to create challenges that easily turn a promising project into an unsure one. Often these issues go hand in hand with a downward spiral of lost time and increasing cost; more so, if includes thermal processing equipment. Let our knowledge and expertise spare you this potential chaos.

IBU-tec has everything you need for your scale-up project: a massive knowledge base derived from many years of testing materials and processes; a versatile lineup of rotary kilns and pulsation reactors; a full set of ancillary equipment for pre- and post-processing; and state-of-the-art laboratories. All of these capabilities in a single company at a single location – in a single package designed to meet your needs. This is the way to a reliable, quick and flexible scale-up strategy.

No limits to the range of applications or the volume of our trials! Minimize your investment risk, assured that your pilot results are complete and verified before transitioning to full-scale production.

Outsource Scale-up and Minimize Investment Risk

You already have a ready developed process or sample material in its final state? IBU-tec will provide you with the necessary boost to production in industrial scale.

With your process parameters determined, defined product specifications and a workable sequence of process steps, we can take the scale-up from there – by an initial verification of the key parameters via a small scale trial.

When a fundamental understanding is lacking, material development data can provide you the critical information to make your project a success.

Flexible trial-concept validation allows your process idea to reach desired production levels quickly. After a successful scale-up process is achieved, you will have all the parameters needed to start industrial scale production – saving time and money.

Quick Scale-up to Start of Production

- Development of process steps to achieve the defined process parameters

- Execution of trials at laboratory scale with full documentation of process conditions and product quality

- Creation of a roadmap for the scale-up process and reproduction of the laboratory results in pilot process equipment