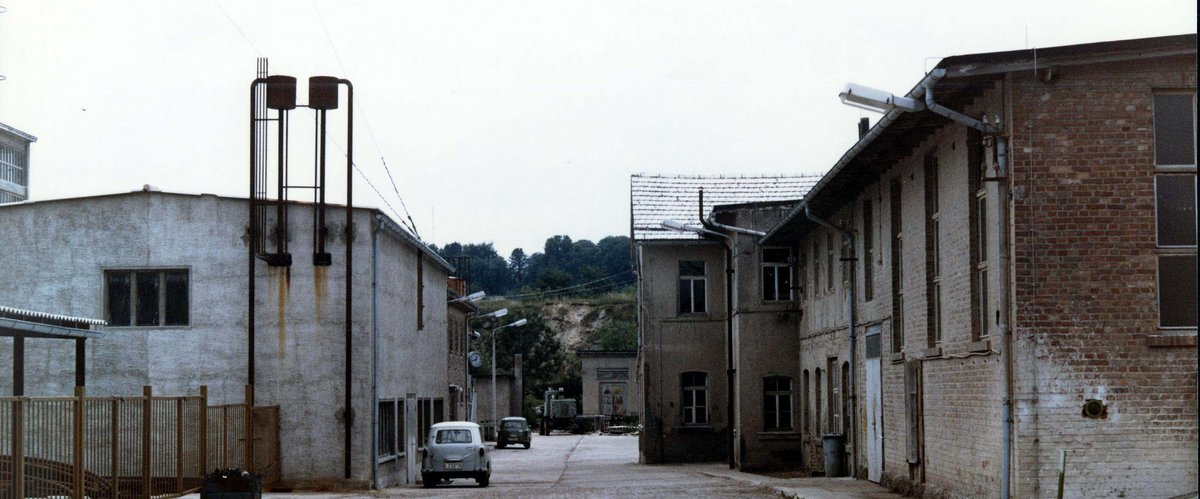

For more than 130 years, experts in thermal process engineering have been working at the Weimar site in Germany. Where a small quarry operated in the 19th century there is now a leading technology center whose expertise and skill in manufacturing and enhancing materials for the chemical industry is in high demand worldwide.

Original Company Founded

1885

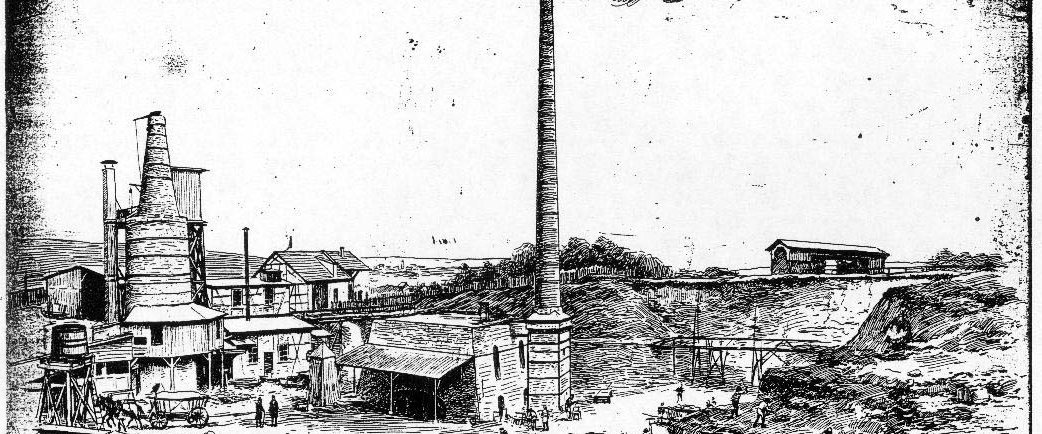

In 1885, a company was founded to manufacture decorative stone from travertine and later to cast stone from quicklime. The processes used at that time, such as crushing, sieving, drying and calcination are still very much a part of our repertoire today.

Restarted Production post World War II

1946

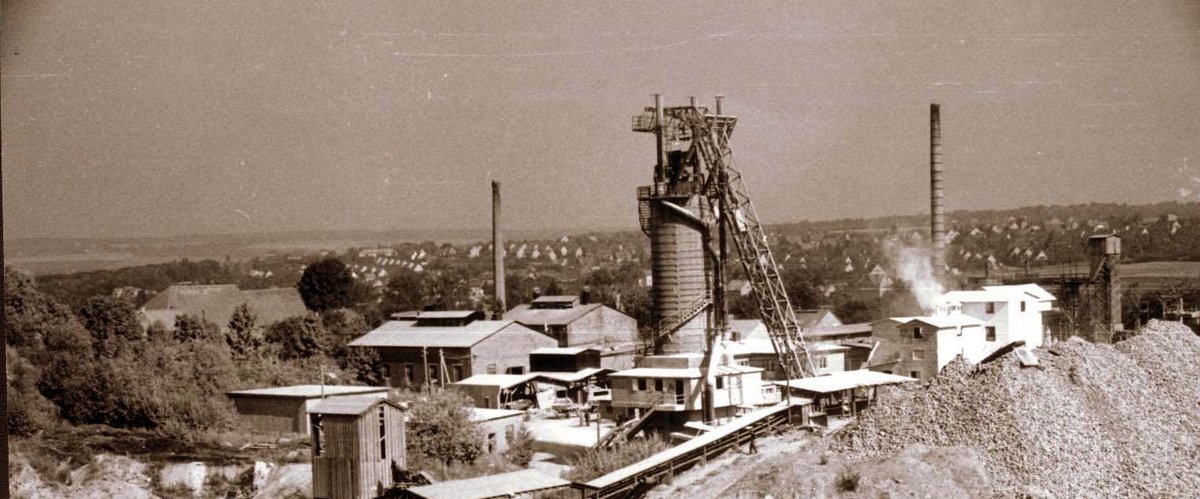

The production of lime was restarted at the site in 1946: Lime was a key element in urgently needed building materials, necessary for reconstruction. A primitive ropeway conveyor was used to transport the building materials across the valley to a nearby railway station.

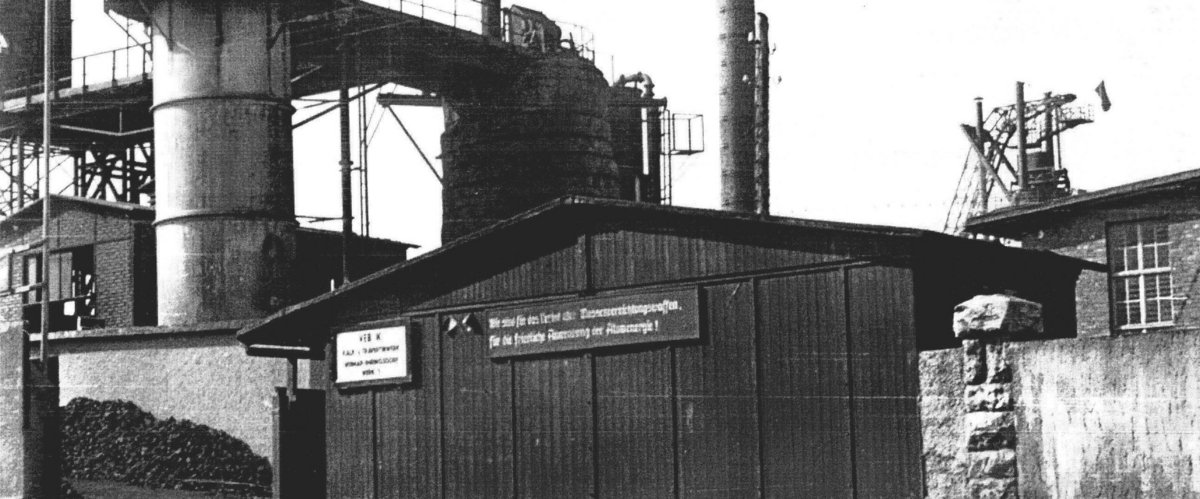

Operations Continue as VEB (nationalized business in the GDR)

1948 – 1974

From 1948, the business operated as the VEB Ehringsdorf Lime and Travertine Works. In 1974, lime production was stopped, bringing a long tradition to an end. Travertine deposits continue to be quarried at the site for high-quality decorative cut stone to this day.

R&D Center Conversion

1975

In 1975 the Weimar SKET-Institute took over the factory site and began using it as a pilot plant. This led to the installation of the first rotary kiln. Since then, analysis, trials and measurements have been part of our core competences. We regard our decades of accumulated experience as one of our most important assets.

R&D Institute Privatization and Reincorporation

1993

In 1993, following the German Reunification, the organization was privatized, founding the ‘Institute for Building Material and Environmental Protection Technologies’. In homage to our history, the initials are still present in our current name: IBU-tec.

Catalyst Research Begins

2001

In 2001, Ulrich Weitz, who later became Chairman of the Board of Management, took over the company and continued to develop it. In addition, research on catalysts was started, since then an important part of our business.

Patenting of the Manufacturing Processes for Submicro Powders in Pulsation Reactors

2005-2009

In 2005, having successfully developed a unique process for creating nano and submicro powders in a pulsation reactor IBU-tec was awarded patent rights. Despite extreme global financial distress, 2008 saw IBU-tec maintain its strategic development plans by investing in new capabilities, constructing the largest pulsation reactor to date.

Addition of Equipment and Client Options

2016

In 2016 IBU-tec installed a new indirect fired rotary kiln (IDO10), once again increasing the options and flexibility we offer to customers.

Initial Public Offering

2017

In order to further company growth and generate new capital for the continued expansion of our client services and capabilities, IBU-tec advanced materials AG went public!

Inauguration of Logistics Centre in Nohra

2017

After extensive reconstruction meausres the new logistics centre in Nohra, about 10 km away from the headquarters of IBU-tec, was inaugurated. The new location is 8,700 square meters large, offers extensive oppurtunities for storage, as well as 500 square meters of modern office space.

Akquisition of BNT Chemicals

2018

A year after its initial public offering IBU-tec acquired BNT Chemicals, a tin chemistry-based company whose product portfolio includes catalysts for the chemical and pharmaceutical industries as well as glass coatings. The added expertise in organometallics provides our customers an ever-greater range of possibilities and solutions.

Opening of Production Site Bitterfeld

2019

Not far from BNT Chemicals, IBU-tec acquired a factory site with a large complex. By 2019, the first rotary kiln was operational and others have followed since then. The chemical park infrastructure affords the new site at Bitterfeld-Wolfen to offer opportunities and capacities that complement the Weimar headquarters.

Launch of IBU-tec Product Portfolio

2021

In addition to the traditional services, IBU-tec introduced a product portfolio in 2021 - high quality powder materials incorporating the considerable know-how in thermal process engineering gained from years in the service business, including our IBUvolt® LFP400 and LFP200.

Management Change

2023

After more than 20 years of heading IBU-tec Group, Ulrich Weitz handed over the chairmanship of the Executive Board to Jörg Leinenbach, who had already been a member of the Executive Board as CFO since 2017. Ulrich Weitz assumed responsibility for the expansion of the battery materials business as Managing Director of the new subsidiary IBUvolt battery materials GmbH.

Present

Four IBU-tec sites operate sixteen rotary kilns, eight pulsation reactors and modern laboratories for customers from all over the world, complemented by a high-quality portfolio of proprietary products. With BNT Chemicals, a subsidiary is successfully active in the production of organometallics and the number of employees has increased from only 20 in the beginning to about 230 in the IBU-tec Group. Our combination of research and development expertise and one of a kind production facilities has seen IBU-tec grow to be an internationally renowned provider to the industry.