Our Milling Technology for Wet Grinding

| Typ | Numbers on site | Typical size | Productivity | Material typ / Grinding tank | Specifications / Special characteristics |

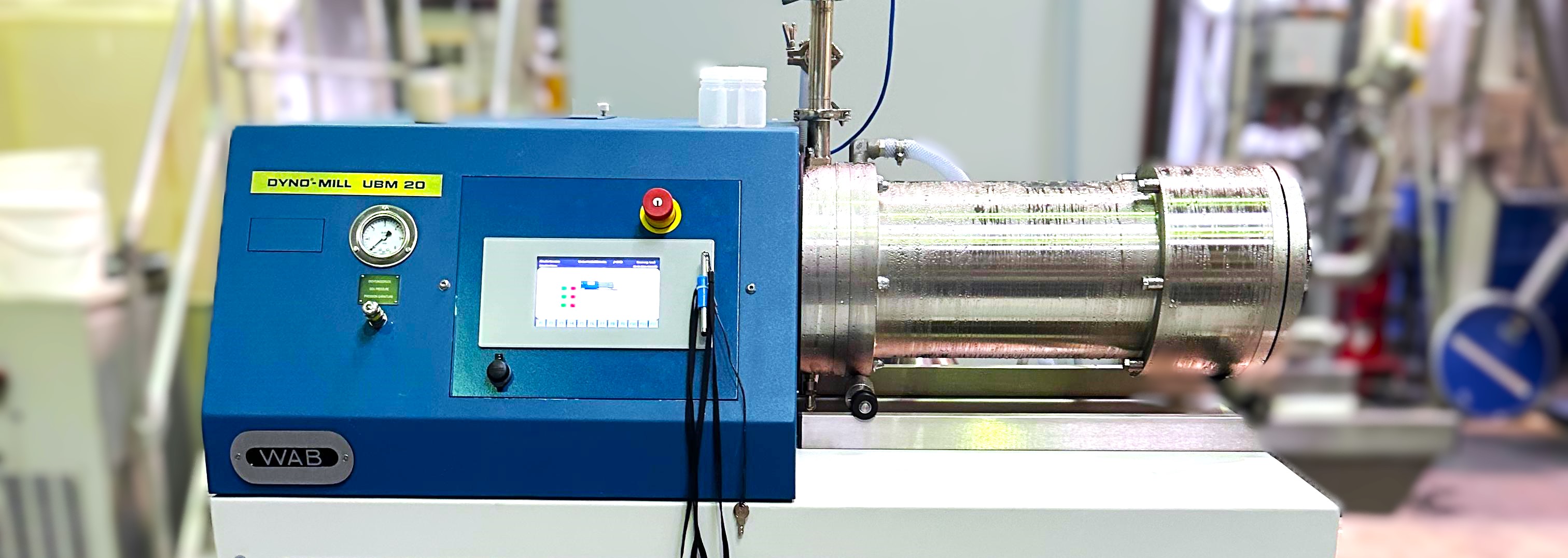

| WAB Mill Willy A Bachofen Dyno© Mill UBM20 | 1 | active milling chamber volume: 17,4 l | up to 500 kg/h | Stainless steel | Agitator Bead Mill |

| Netzsch Zeta RS | 1 | active milling chamber volume: 2,0 l | up to 100 kg/h | Silicon carbide / ZrO2 rotor | Agitator Bead Mill |

| Netzsch Lab Star | 1 | active milling chamber volume: 0,54 l | up to 20 kg/h | Y-stabilized zirconium oxide or polyurethane (PU) | Agitator Bead Mill |

Our Milling Technology for Dry Grinding

| Typ | Numbers on site | Air volume | Grinding gas | Attainable throughput | Material typ Grinding tank/ Classifying wheel | Specifications / Special characteristics |

Noll

| 1 | max. 100m³/h | Nitrogen,

| up to 6 kg/h | Stainless steel / Ceramics, Stainless steel | Opposed jet mill |

Efficient Grinding Technology for precise Material Processing

Contract grinding and deagglomeration of powders and fine granules are key parts of our process engineering services. We utilize modern grinding technology to efficiently and precisely reduce materials to specific, fine particle sizes. Our milling equipment supports a wide range of applications, including product development, process optimization, pilot projects, and the production of sample quantities or small batches for market and application testing.

Our facility features three different types of mills: multiple agitator bead mills, a jet mill, and two pin mills. These systems differ not only in their achievable throughput but, more importantly, in their fundamental mechanical grinding principles. This diversity allows us to meet various grinding objectives—from pre-grinding and achieving defined particle size distributions to producing extremely fine powders.

Through numerous customer projects, we have developed deep expertise in processing a wide array of materials. We understand that each grinding task has unique requirements based on the raw material's physical properties, the target fineness, and the final application. Therefore, we carefully analyze each inquiry to determine if it can be accomplished with our existing technology. If a project requires specialized capabilities, we can leverage our extensive network of experienced partners to reliably execute even the most demanding tasks.

With our technical equipment, process knowledge, and years of experience, we are a competent partner for industrial contract grinding—delivering precision, flexibility, and high quality standards.