Process Development & Engineering

A – Laboratory

In the laboratory, we will determine the feasibility of your process concept: Your raw material will be analyzed implemented in batch operation as realistically as possible. Generated data gained determines initial process parameters. Customers will receive invaluable information which form the basis for subsequent pilot trials.

Results:

- Determination of fundamental feasibility

- Recreation of the thermal Process with lab equipment

- First information about process parameter

- Establishment of necessary process steps

B – Pilot Scale

In our pilot kilns, the process parameters for continuous operation will be established, ideally confirmed in a small industrial production plant. You will gain essential data about your process in a rotary kiln in continuous operation, which will serve as the foundation for the succeeding basic engineering.

Results:

- Comprehensive information about your process during rotary kiln continuous operation: All relevant parameters, including material handling, waste gas composition and emissions

- Optimization of process parameters

- Establishing the foundation for a succeeding basic engineering study

C – Basic Engineering Study

Based on the preceding process development, your entire plant can be designed and dimensioned from a thermal processing perspective. As an end result, you will receive the comprehensive understanding needing for decision-making and further planning of your plant.

Results:

- Calculation of all main material flows (mass flow rate and composition)

- Design of the entire plant’s main components

- 3D draft with a fundamental installation plan

- Profitability analysis with estimate of investment and operating cost

Optimization and Retrofitting of Rotary Kilns

Your existing equipment often contains hidden optimization potential to uncover and exploit:

- Improve your product quality

- Increase your production volume

- Increase uptime

- Reduce operating costs

With a core business firmly rooted in contract manufacturing, IBU-tec has garnered several decades of experience in planning, operating, converting and optimizing plant systems according to individual needs and customer requirements. Employ that expertise to get custom-made solutions for optimizing and retrofitting your rotary kilns and the associated equipment.

- Process and plant optimization with on-site measurements of client facilities, trials conducted in our facilities and state-of-the-art process simulation software

- Comprehensive, systematic analysis to uncover vulnerabilities in your existing systems or reveal potential problems during the planning phase

- Process Balancing and Optimization Using On-Site-Measurements

Process Balancing and Optimization Using On-Site-Measurements

Expertise is crucial to maximizing the full potential of your kiln systems:

- Using the correct measuring technology to precisely record the operating state. Oftentimes, client-specific equipment modifications will be necessary.

- Essential measuring positions are often particularly difficult to reach or inaccessible.

- Measurements under adverse process conditions (e.g. temperatures up tp 1000°C inside the kiln and high dust contents).

Once a precise evaluation of the measurement data has been performed, solutions for optimization are established. Let our team present specific recommendations for optimized operations or process design, based upon our decades of experience. Subsequent analysis of material and energy flows lay the foundation for further optimization.

Process Data Measurements:

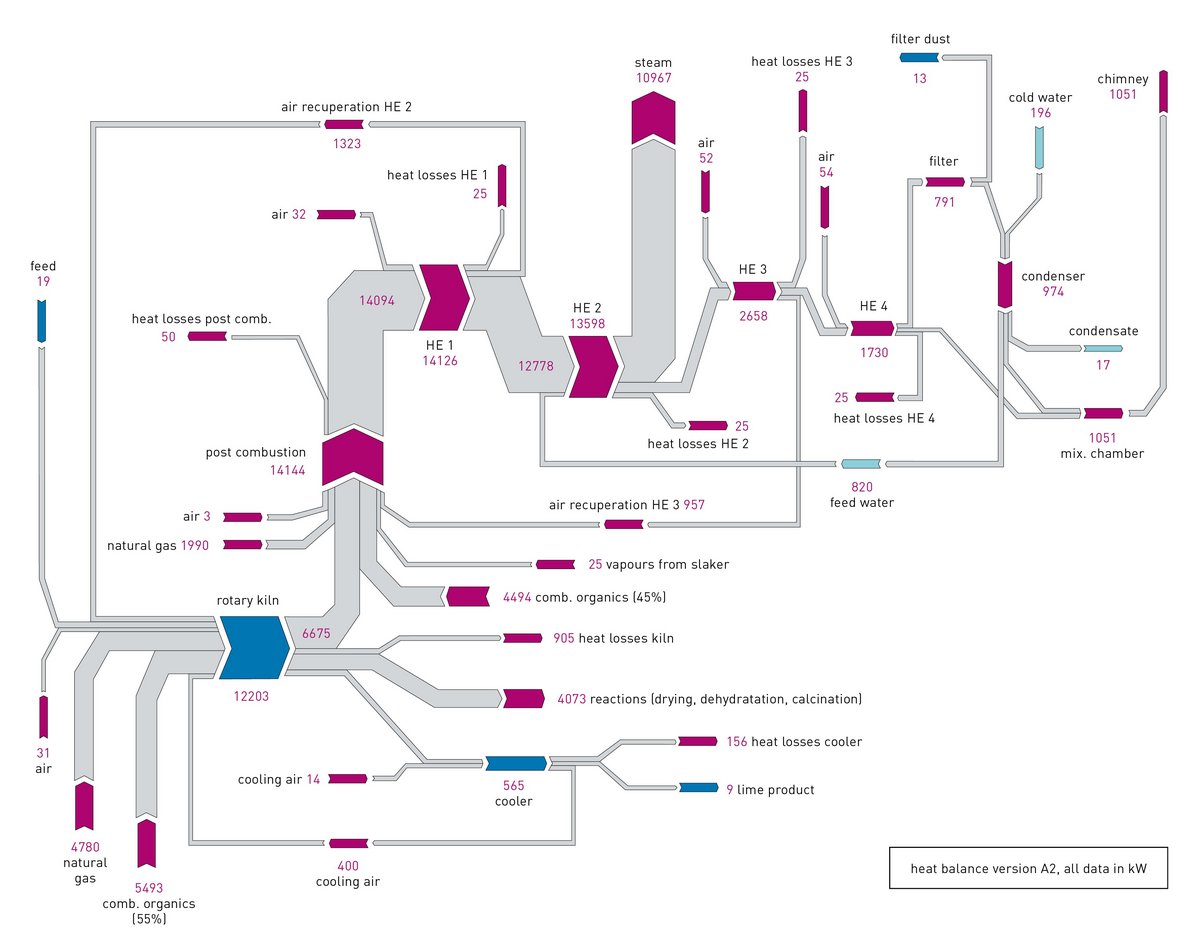

- Mass balances, thermal balances and heat flow measurements in plants and plant components

- Measurement of volume flows, process gas composition, dust quantities, gas, material and wall temperatures, also in the raw gas and within the kiln, even in high temperature ranges

- Determination of gas concentrations in the exhaust gas and within the rotary kilns (e.g. O2, CO, CO2, H2O, NO, NO2, SO2, HCI, HF, TOC etc.)

- Determination of filter separation efficiencies, heat losses and incorrect air volumes

- Examination of corrosive exhaust gases

- Process Optimization in Pilot Plants

Process Optimization in Pilot Plants

Another optimization approach is the simulation of your processes in IBU-tec’s pilot plants: A wide variety of rotary kilns in different sizes and designs with corresponding material handeling equipment, allow for testing varying process parameters or different kiln internals in order to correctly calculate the best optimization protocols, resulting in:

- Increase in product quality and reduction of unwanted by-products

- Improvement of heat transfer in the rotary kiln to increase production volume

- Reduction of the dust concentration in the flue gas to allow the application of smaller, more cost-effective separators

The flexibility to adapt kilns to your specific requirements, combined with our years of experience in process development, offer you an effective test platform without impacting your ongoing production. An adjoining laboratory provides expertise in processing technology, experimental kilns, as well as chemical, mineralogical and fuel analyses.

- Optimization through Process Simulation

Optimization through Process Simulation

Process simulation and balancing through software tools represents a third possibility to carry out an optimization or retrofit of your rotary kilns. The material and heat transport processes occurring inside the rotary kilns will be recreated digitally, including occurring chemical reactions. Additionally, already measured data can be validated, thus increasing its reliability and usability.

With these calculations, we can recommend firmly grounded measures: These can be ideas for increasing throughput, reduced energy and raw materials use, changes in process parameters or a feasibility study for new products.

These simulations will also form the basis for designing a new rotary kiln and provide data for improvements to existing plants and/or processes, immensely improving results.

- Weak Point Analysis in an RCM-Workshop

Weak Point Analysis in an RCM-Workshop

With the RCM method (reliability centered maintenance), you establish a proactive, targeted system with the goal to maximize uptime and system availability.

A failure risk analysis for each relevant assembly (e.g. the trunnion wheels of your rotary kilns) is generated during the workshop, uncovering the consequential threats to plant availability, product quality, environment and plant safety, as well as delayed / missed deliveries and possible relevant legal ramifications.

On the basis of this matrix, optimal, client specific countermeasures are developed to protect your critical components and increase their overall reliability. When the RCM method is implemented on your behalf, you will receive the following information:

- Documentation of technical vulnerabilities and associated risks; Recommendation of appropriate mitigation measures

- Detection of other technical risks, such as improper operation, unsuitable components, inappropriate choice of materials, etc.

- Assessment of maintenance measures to date, with a particular emphasis on economic considerations

- Development of measures to optimize maintenance and spare parts inventory

- Quantification and assessments of failure risk

Consulting Owners Engineering for Rotary Kilns and Thermal Plants

Consultancy in the planning of thermal analysis parks from pilot to production plants - as an independent partner with decades of expertise in the operation and process-specific adaptation of rotary kiln plants. Evaluation of process layouts and proposals enables you to make confident decisions. We help you with the layout and design of equipment and evaluate offers from manufacturers and suppliers independently and in your interests. We can accompany you throughout your project over several months and are available in phases where you need support. Your advantage: A contact person with expertise who can clarify planning issues quickly and easily.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_Engineering_Optimization_rotary_kilns_service_0b66fc5251.jpg)